Digital development & rapid prototyping

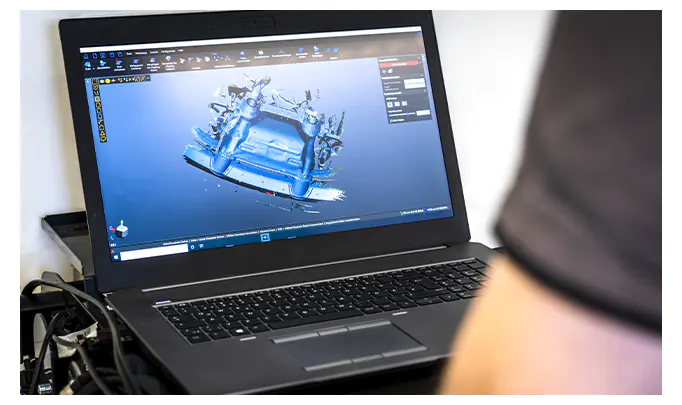

3D scanning for the electronic measurement of vehicles

Electronic vehicle measurement using 3D scanning is a pioneering method for creating exact digital images of vehicles. The process delivers fast, precise and cost-effective results that serve as the basis for exact designs and further development processes. This considerably shortens the development time.

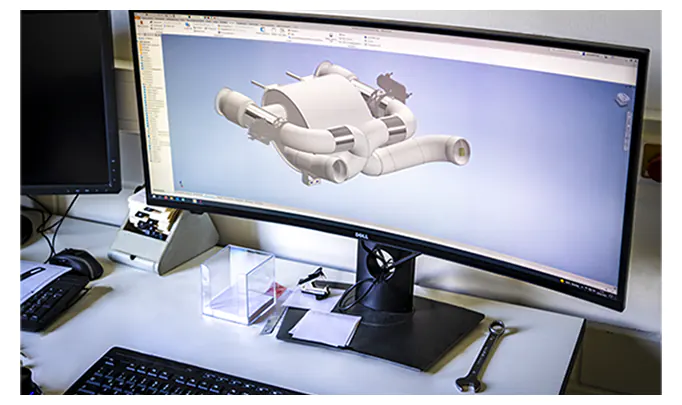

CAD design based on the scan data

The measurement data obtained using 3D scanning is further processed in high-performance CAD systems. This is where detailed designs and optimized component geometries are created that are precisely matched to the real vehicle dimensions. This process enables precise adjustments and guarantees the highest quality and accuracy of fit of the components.

3D printing for prototypes and production gauges

The CAD drawings are transferred directly to modern 3D printers to quickly produce initial prototypes or production gauges. This additive manufacturing process enables components to be checked quickly and flexibly with regard to functionality, design and usability, thereby efficiently optimizing production processes.

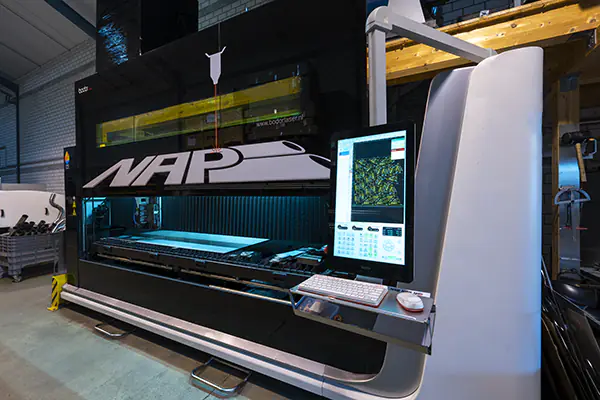

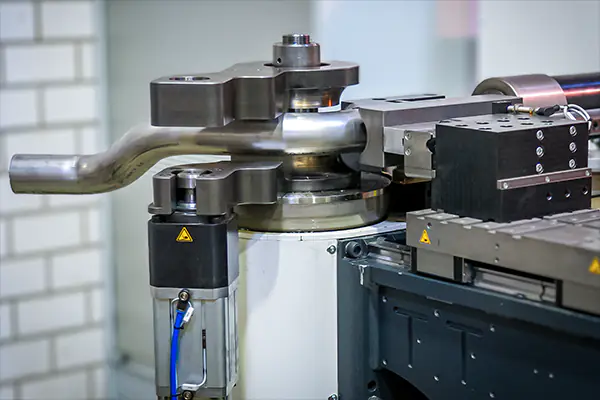

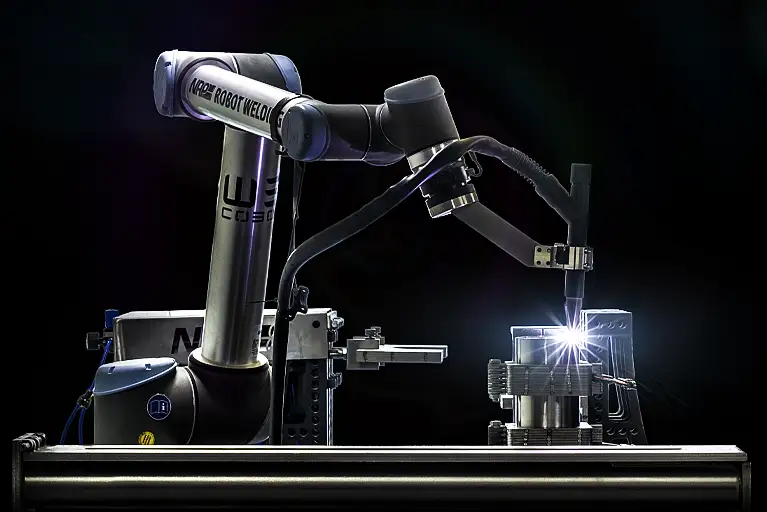

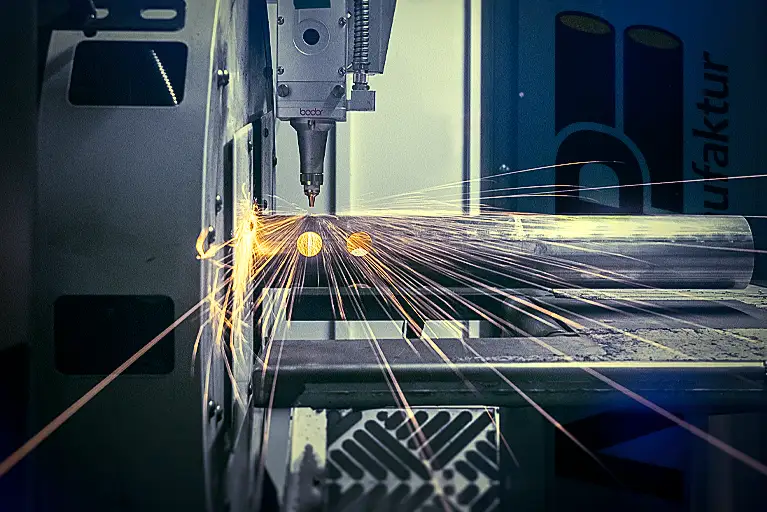

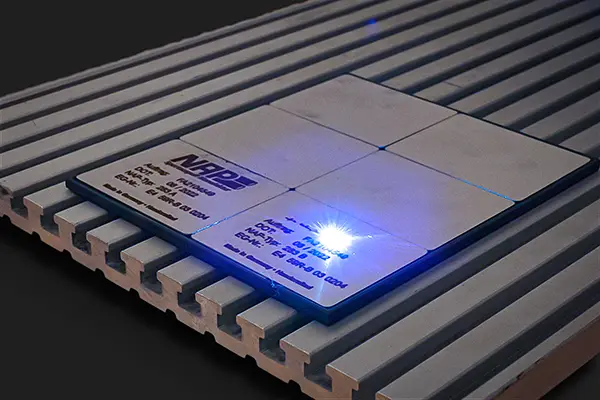

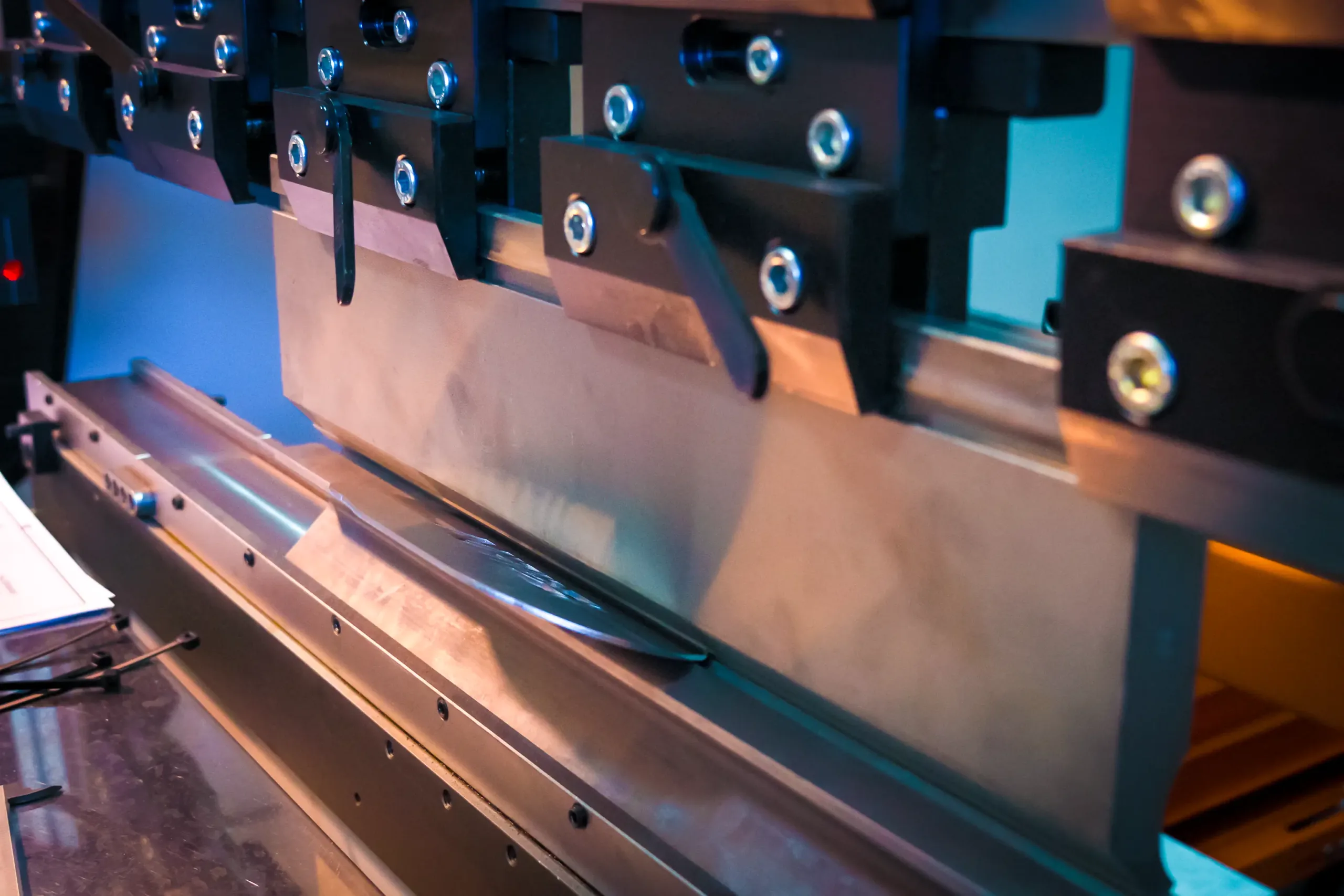

Networked series production

Networked series production is a technology that enables us to make production more efficient and cost-effective. By linking production facilities, using automation technologies and communicating via industrial networks, we can achieve faster production and higher product quality. In addition, networked series production can also contribute to the optimization of production logistics, as important data from the production processes can be called up and evaluated immediately.